Are you curious about just how high-tech and eco-friendly our travel bags and backpacks are? If so, this post is here to provide a lot of tasty tidbits of info and will hopefully answer any questions you might have about that. We also hope that after reading it, you’ll get a warm and fuzzy feeling knowing that we’re taking such care to only have the highest quality standards and minimize the environmental impact during that process… Enjoy!

Bluesign® Fabric

Our main tech fabric supplier is LeejoTex and they are Bluesign Certified. Wow cool, but what does that actually mean?! The term “bluesign” comes from the name of a Swiss group called Bluesign® Technologies. This group monitors the complex journey of materials from factory to final product. The bluesign® team includes experts in chemistry and textile production, as well as specialists who oversee a robust system of factory auditing and certification. If a fabric manufacturer such as LeejoTex, gets the stamp of approval from Bluesign, it means they have met the rigorous standards of this group to ensure minimal environmental impact during production and quality working standards.

Oeko-Tex & YKK Zippers

All the hardware like zippers, buckles, straps, snaps and other bits and bobs in addition to the tech-fabrics are Oeko-Tex Standard 100 certified. Again, that sounds fancy, but what is it?! Oeko-Tex looks into the chemistry of the materials to certify that they are free of harmful chemicals and are safe for human use. Here’s an excerpt from them: "If a textile article carries the STANDARD 100 label, you can be certain that every component of this article, i.e. every thread, button and other accessories, has been tested for harmful substances and that the article therefore is harmless in human ecological terms. The test is conducted by our independent OEKO-TEX® partner institutes on the basis of our extensive OEKO-TEX® criteria catalog.”

Also, what’s all the hype over YKK zippers? Well, simply put, they’re the best, the gold standard and why a majority of the top fashion and accessories brands out there use them. And because of the quality, they’re really expensive and why you’ll usually only see YKK on premium products.

Recycled Backpacks & Travel Bags

One of the main fabrics we use and are very proud of is our 600 denier PET, which is made from 100% post-consumer recycled plastic bottles. The difference between ‘post-consumer’ waste versus ‘pre-consumer’ is an important distinction to make. A lot of brands that boast Green Washing techniques in their marketing actually use pre-consumer waste. However, while technically it is recycled, it doesn’t do much in the way of corrective action. Instead, it takes excess trimmings left over from manufacturing processes and up-cycles it into something else. That said, eliminating waste is good and pre-consumer recycled products are still better than non-recycled products.

‘Post-consumer’ waste is the one we care about because it actually cleans up the planet. The journey of our PET fabric starts with the gathering of discarded PET plastic bottles. PET or polyethylene terephthalate is commonly used to package soft drinks, soap, shampoo and various other liquids.

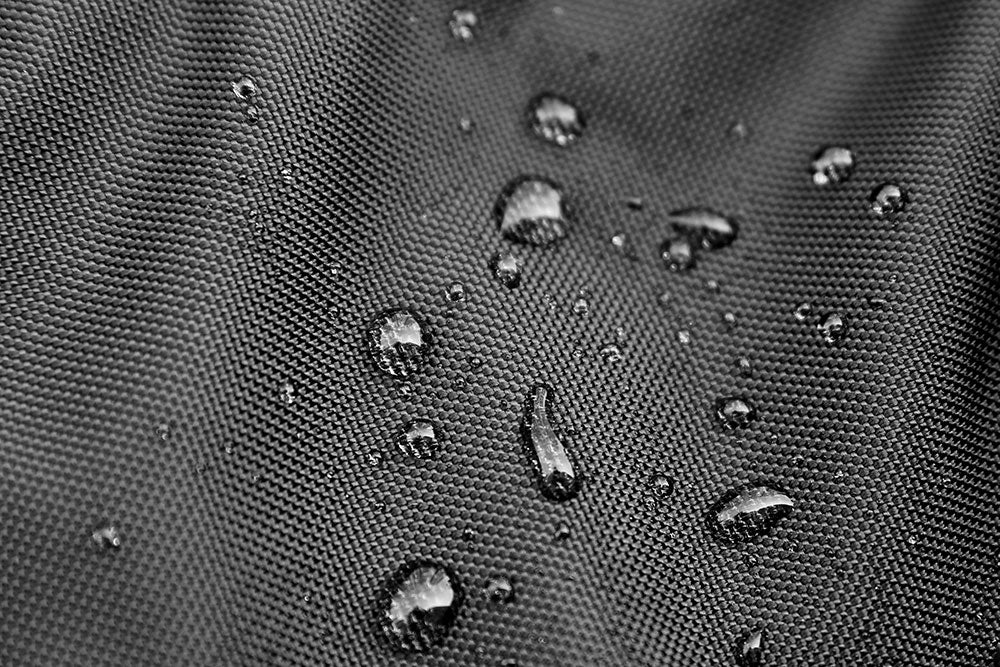

The bottles are then washed, compressed and reground into filament flakes. The filament flakes are then put into a hopper, melted down, extruded into yarn and then woven into fabric. After the fabric is woven, it’s coated for waterproofing, sent to our workshop in Vietnam and assembled into finished bags & backpacks, woohoo!

Renewably powered

The factory in China that gathers the discarded plastic bottles and recycles it into the yarn that LeejoTex purchases is called Haili Green Fiber Co. and they treat and reuse 95% of their wastewater and is 10% solar powered. It’s not 100%, but it’s definitely a step in the right direction!

Tech fabrics with a lifetime guarantee

Some other notable materials such as our 840-denier ballistic nylon and honeycomb ripstop lining are important key players not to exclude. This combo of materials create the nearly indestructible and waterproof shell on our lifetime guarantee products and are eco-friendly in their own way. Our lifetime guarantee means we’ll fix them if they break, meaning your bag will never end up in a landfill, or at the very least, will take a damn long time to do so!

On the soft side

Because nearly all of us live a digital lifestyle that requires us to carry around various gadgets and hardware, it’s important to have a reliable bag that has padded protection for impact resistance and cushy non-scratch lining like our fuzzy tricot. And of course, the material that gives the heart and soul to all of our products are the artisan fabrics handmade in Ghana, Guatemala, India, Indonesia & Vietnam. Read more about our partnering artisans and their amazing process here.

Responsibly made

Last, but certainly not least, is our production in Vietnam, the magic makers behind your bags! Our sewing workers are paid a wage that is 80% higher than the minimum for sewing workers in Vietnam. Each worker is provided with two weeks' paid holiday time off, maternity leave, health insurance, unemployment benefits, social security and a travel & food stipend. With all benefits included, our workers are paid 140% more than minimum wage for sector 1 industry standard (according to the VN Ministry of Labor). The average age of our crew is 24 and is comprised of roughly 70% women and 30% men. We like to play team sports, go on trips and celebrate birthdays, weddings and personal achievements together. We’re currently moving to a new workshop that will have a higher level of environmental standards, a much larger space, and we will be applying for ISO14001 certification.

Hopefully you enjoyed this info and understand a bit more about the incredible materials that make up the bag that carries your goodies every day.